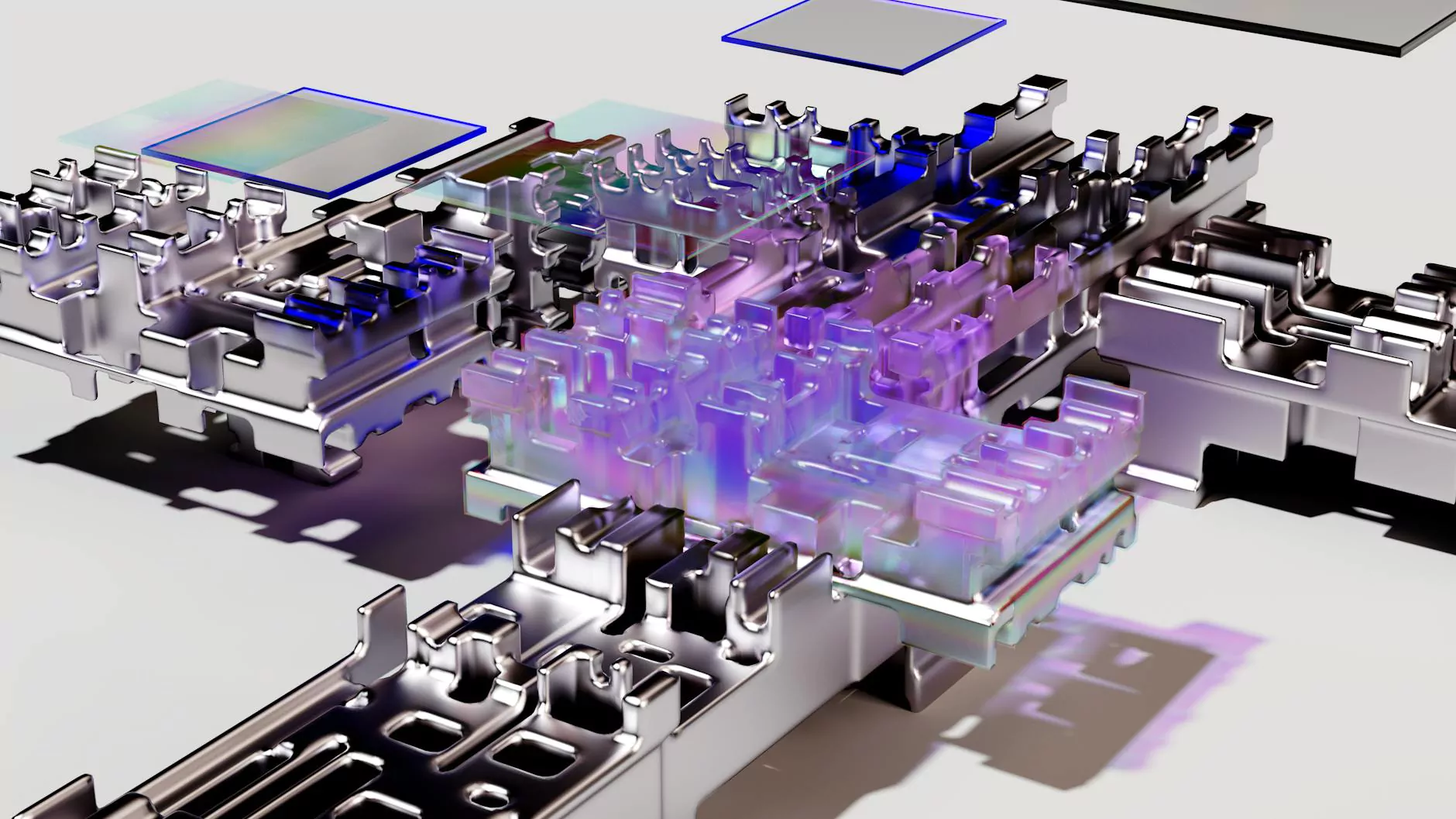

CNC Machining Factory: Revolutionizing Metal Fabrication

In today's highly competitive manufacturing landscape, a CNC machining factory plays a pivotal role in delivering precision-engineered components. With the evolution of technology, CNC (Computer Numerical Control) machining has transformed how metal fabrication is approached. This article will delve into the various aspects of CNC machining, detailing its benefits, applications, and the unparalleled services offered by DeepMould.net, a leading player in the metal fabrication industry.

Understanding CNC Machining

CNC machining is a process that automates the movement of machining tools through programmed computer software. This technology harnesses the power of computers to drive tools such as lathes, mills, and routers with incredible accuracy. Here are some essential elements that define the CNC machining process:

- Precision: CNC machines can achieve tolerances of up to ±0.001 inches, ensuring that each component is manufactured with utmost accuracy.

- Automation: Once programmed, CNC machines can run continuously with minimal human intervention, significantly improving productivity.

- Complexity: CNC technology allows for the creation of intricate designs that would be nearly impossible to achieve by traditional machining methods.

- Versatility: CNC machining can be applied to a variety of materials, including metals, plastics, and composites, making it suitable for diverse applications.

The Importance of CNC Machining Factories

CNC machining factories are critical in various industries, providing solutions that require high precision and consistency. Here’s why they are essential:

1. Enhanced Productivity

In a CNC machining factory, automated processes reduce human error and allow for higher operational speeds. Machines can operate twenty-four hours a day, significantly increasing production output.

2. Cost Efficiency

While the initial investment in CNC machinery can be high, the long-term savings through reduced labor costs and less material waste make it a financially sound decision for businesses.

3. Consistency and Quality Control

The programmable nature of CNC machining ensures that each part produced is identical to the last. This consistency is crucial for industries where failure to meet specifications can lead to significant costs. Accurate quality control measures embedded in the CNC process enable factories to maintain high standards.

CNC Machining Applications Across Industries

The versatility of CNC technology allows it to be effectively utilized across various sectors. Below are some of the primary industries that benefit from CNC machining:

1. Aerospace Industry

In the aerospace sector, the demand for precision parts is paramount. CNC machining plays a crucial role in manufacturing components such as turbine blades, structural components, and brackets. The ability to work with lightweight and durable materials is vital in this industry.

2. Automotive Industry

The automotive industry relies on CNC machining for crafting intricate parts such as engine components, transmission housings, and intricate wheel designs. Quality and efficiency in production mean a greater competitive edge.

3. Medical Devices

Medical devices require a high level of precision and compliance with strict regulations. CNC machining enables the production of intricate components, such as surgical tools, implants, and diagnostic instruments, ensuring reliability and safety in healthcare.

4. Electronics Manufacturing

The electronics industry often requires the manufacture of small, precise components such as housings, connectors, and circuit boards. CNC machining meets these needs through its ability to handle small tolerances and complex designs.

Benefits of Choosing a Professional CNC Machining Factory

When considering CNC machining services, partnering with a reputable CNC machining factory like DeepMould.net provides numerous advantages:

1. Expertise and Experience

With years of experience in metal fabrication, a professional CNC machining factory possesses the skills and knowledge to handle complex projects efficiently. Their team can offer valuable insights into design optimization and production methodologies.

2. Advanced Technology

Leading CNC machining factories invest in state-of-the-art equipment and technology, ensuring high precision and efficiency in their operations. By leveraging these resources, clients can achieve superior product quality.

3. Custom Solutions

Every project has unique requirements. A dedicated CNC machining factory will provide personalized solutions tailored to the individual needs of each client, ensuring optimal results and client satisfaction.

4. Comprehensive Services

In addition to CNC machining, many factories offer a range of complementary services, including design assistance, prototyping, and finishing. This one-stop-shop approach simplifies the process, allowing clients to streamline their supply chain.

How DeepMould.net Stands Out in CNC Machining

DeepMould.net has established itself as a leader in the CNC machining sector, known for its commitment to quality and customer satisfaction. Here are some factors that make DeepMould.net a standout choice:

1. Commitment to Quality

Quality is at the forefront of DeepMould.net's operations. With stringent quality control processes and certifications, clients can be assured that the products will meet or exceed industry standards.

2. Skilled Workforce

The proficiency of the staff at DeepMould.net is unmatched. With continuous training and a focus on professional development, the team is well-versed in the latest CNC technologies and machining techniques.

3. Sustainable Practices

DeepMould.net is dedicated to sustainability, utilizing eco-friendly practices in their manufacturing process. This not only reduces the environmental impact but also appeals to clients looking to partner with socially responsible companies.

4. Customer-Centric Approach

At DeepMould.net, the customer is always a priority. Their responsive customer service and collaborative approach ensure that clients' needs are met throughout the manufacturing process, fostering long-term relationships.

The Future of CNC Machining

As technology continues to advance, the future of CNC machining looks promising. Innovations such as artificial intelligence and machine learning are set to transform how CNC machines operate, leading to even greater efficiencies and capabilities. Here’s a glimpse of what the future holds:

1. Increased Automation

The integration of AI will allow for more sophisticated automation, enabling factories to operate autonomously and optimize production schedules based on real-time data.

2. Enhanced Customization

Advancements in software will facilitate easier customization and faster turnaround times, allowing manufacturers to respond quickly to market demands and consumer preferences.

3. Sustainability Innovations

With an increasing focus on sustainability, CNC machining factories may implement greener technologies and practices, further reducing the environmental footprint of production.

Conclusion

In conclusion, the role of a CNC machining factory in modern manufacturing is crucial. By offering unparalleled precision, efficiency, and innovation, CNC machining represents the future of metal fabrication. Whether you are in the aerospace, automotive, or medical device industry, choosing a reputable partner like DeepMould.net ensures that you receive quality service tailored to your needs. As CNC technology continues to evolve, the opportunities will be limitless, paving the way for advancements in various sectors and redefining manufacturing as we know it.