Understanding CMYK Printer Ink: The Key to High-Quality Printing

The world of printing has evolved tremendously over the past few decades, and one of the pivotal components that has played a vital role in this evolution is CMYK printer ink. Whether you're a graphic designer, a marketing professional, or a business owner, understanding the basics of CMYK ink can tremendously enhance the quality of your printed materials. This article will delve deep into what CMYK printer ink is, its benefits, and how you can effectively use it in your printing services.

What is CMYK Printer Ink?

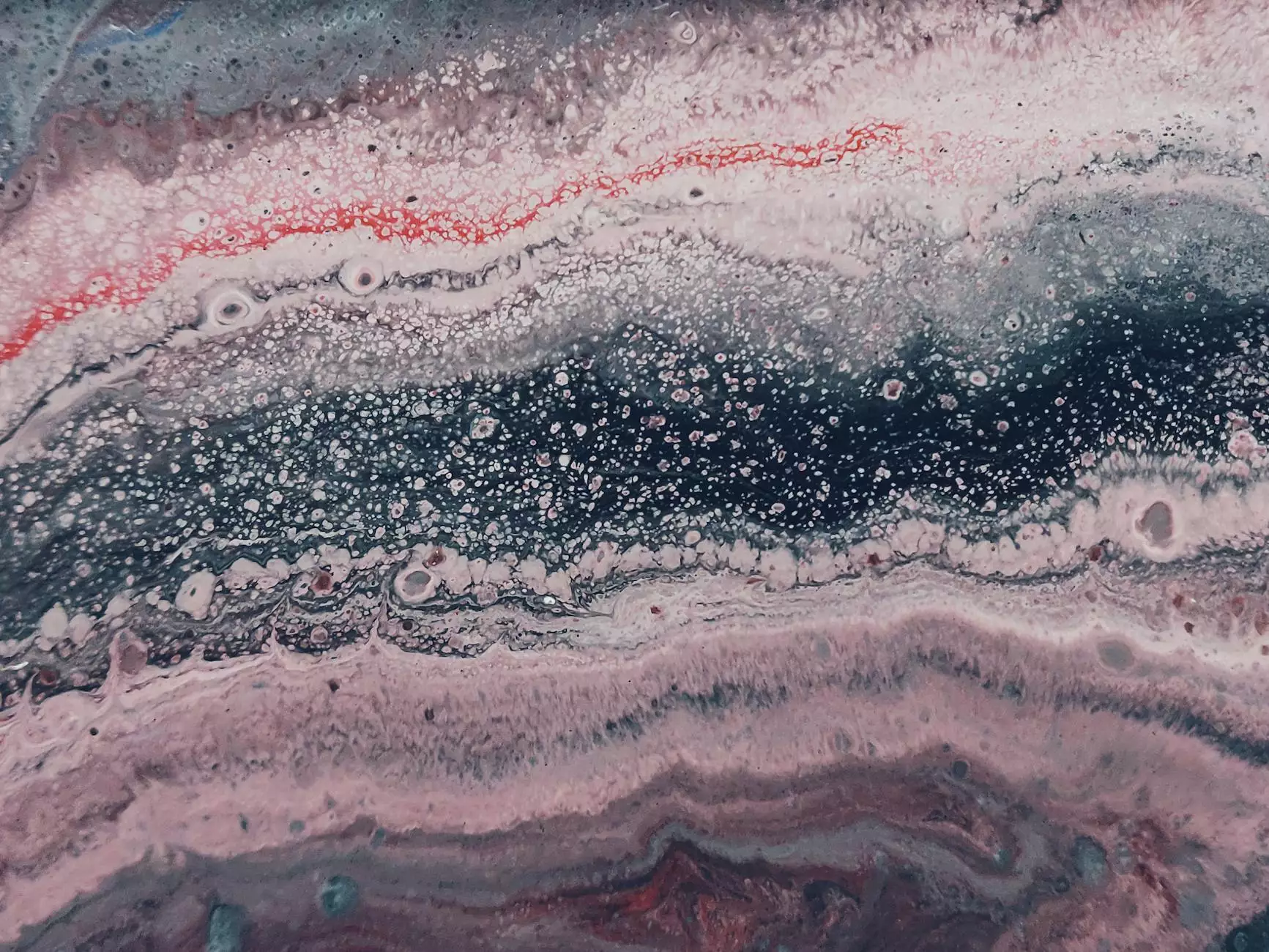

CMYK stands for Cyan, Magenta, Yellow, and Key (Black). These four colors are the primary colors used in color printing. When combined in various proportions, they can produce a vast spectrum of colors. Here’s a deeper look at each component:

- Cyan: A bright blue that absorbs red light.

- Magenta: A vibrant red that absorbs green light.

- Yellow: A cheerful hue that absorbs blue light.

- Key (Black): Used for depth, contrast, and detail, it absorbs all colors of light.

The Importance of CMYK in Printing Services

When it comes to printing services, the quality of output relies heavily on the inks used. Here’s why CMYK is integral to the printing process:

1. Accurate Color Representation

The combination of the four colors allows for a >broad range of colors. It utilizes the subtractive color model, which means that as more colors are added, the result becomes darker. This is crucial for professionals who need to ensure that their printed materials accurately reflect their brand colors or artistic intentions.

2. Cost-Effectiveness

Using just four inks means reduced costs in comparison to printing with multiple color inks. The CMYK printer ink system can produce a wide variety of colors without the need for multiple additional cartridges, simplifying inventory management and reducing waste.

3. High-Quality Output

CMYK inks are designed for high-quality printing. They provide vibrant and rich colors, ensuring that images come out with the depth and shadows necessary for a professional finish. This is especially crucial in industries like marketing, advertising, and fine arts.

Types of CMYK Printer Ink

There are several types of CMYK inks available, each varying in formulation and purpose:

1. Dye-Based Inks

Dye-based inks are known for their vibrant colors and smooth application. They are ideal for printing images on coated paper and produce stunning results but can fade when exposed to sunlight.

2. Pigment-Based Inks

Pigment-based inks are more lightfast compared to dye-based inks. They are less likely to fade over time, making them a suitable choice for archival printing. They work well on various materials and are versatile in usage.

3. Eco-Solvent Inks

Eco-solvent inks are a healthier alternative for outdoor graphics. They produce vibrant colors while being less harmful to the environment, making them increasingly popular for signage and banners.

How to Choose the Right CMYK Printer Ink

Selecting the appropriate CMYK printer ink can be overwhelming given the vast array of options available. Here are some considerations to guide your choice:

1. Printing Purpose

Define what the print job is for. For short-term projects like flyers or posters, dye-based inks might suffice. However, for long-term prints such as photographs or archival documents, consider pigment-based inks.

2. Surface Compatibility

Different inks work better on different surfaces. Make sure the ink you select is compatible with the medium you wish to print on, whether it’s glossy paper, canvas, or vinyl.

3. Print Method

Evaluate your printing method. Inkjet printers often use dye-based or pigment-based inks, while laser printers typically require toner cartridges.

The Process of Printing with CMYK

Understanding the printing process with CMYK printer ink involves several steps. Here’s how it typically goes:

1. Design Creation

Start with designing your project in graphic design software. Ensure the design is in CMYK color mode to maintain color accuracy.

2. Color Separation

The design is then separated into the four color channels. Each channel corresponds to one of the CMYK colors and determines how much ink will be applied for that color in the printing process.

3. Printing Setup

Prepare your printer by loading the respective CMYK inks. Ensure that the printer settings are configured to the correct paper size and print quality.

4. Printing

Finally, execute the print command. The printer will apply the inks layer by layer, starting with one color at a time until the full design is realized.

Maintaining Your CMYK Printer Ink

Caring for your printer and its inks is crucial to ensure optimal functionality and output quality:

1. Regular Cleaning

Keep your printer clean by performing regular maintenance checks and cleaning cycles. This prevents clogs and ensures smooth ink flow.

2. Proper Storage

Store your CMYK printer ink in a cool, dry place to prolong its shelf life. Ensure cartridges are sealed and protected from direct sunlight.

3. Use Regularly

Regular use of your printer helps keep the ink flowing. If a printer is left idle for too long, the ink may dry up and clog print heads.

Conclusion

CMYK printer ink is a cornerstone of the printing industry, enabling high-quality, vibrant prints essential for various applications. By understanding the nature of these inks, choosing wisely based on your needs, and properly maintaining your printing equipment, you can significantly enhance your printing projects. As Boston Industrial Solutions provides premium printing services, leveraging your knowledge of CMYK inks will ensure your printed materials stand out in today's competitive market.

For more insights into printing services, be sure to explore the offerings at bostonindustrialsolutions.com and elevate your printing standards today!